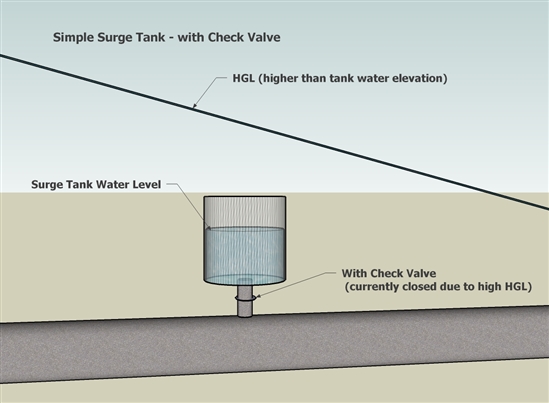

They are also used if backflow will cause damage to equipment upstream that can only allow media to flow in one direction. For example, a sewer line will have a non return valve to ensure that waste can leave but not re-enter the system. Backflow can cause an issue if the backflow is contaminated, and therefore, contaminates the media upstream. However, since they are non return valves, they are a cheap, effective, and easy solution to solve a potential issue. They are commonly installed in applications that backflow would cause an issue. Unlike other valves, they do not need a handle, lever, actuator, or human to correctly work. Depending on the valve type, the closure mechanism is different. When the pressure is higher on the outlet side (or the input side pressure is not high enough), the valve will close. They require a higher pressure on the input side of the valve than the output side to open the valve. Figure 1 shows an example of a check valve.Ī check valve relies on a pressure differential to work. Since they only allow media flow in one direction, they are commonly referred to as ‘one way valves’ or ‘non return valves.’ The main purpose of a check valve is to prevent backflow in the system. They have two ports, one as an inlet for the media and one as the output for the media. A check valve is a device that only allows the flow of fluids in one direction.

0 kommentar(er)

0 kommentar(er)